Radon is a naturally occurring radioactive gas that is released through the decay of elements such as uranium, thorium and radium found in soil and rocks. There is no escaping radon gas entirely, and no radon gas level is deemed safe. Fortunately, the gas disperses in the air so that most outdoors levels are low. The problem occurs when there is a build up of radon gas in the home that cannot readily escape. Remedial actions should be initiated where airborne radon levels exceed 4 pCi/L and water radon levels are above the 20,000 to 25,000 pCi/L range. Note that the numbers for air and water are different.

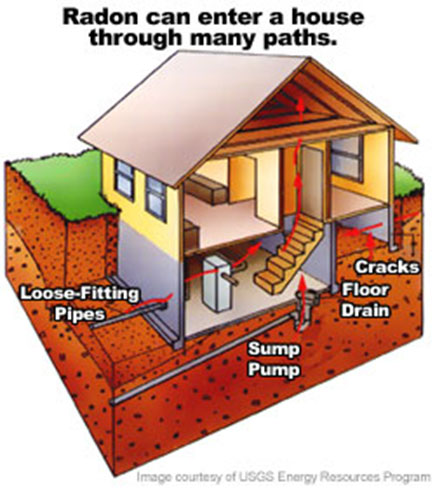

Radon gas cannot be detected through the senses. It is tasteless, colorless and odorless. People who inhale substantial amounts of radon gas are at an increased risk of developing lung cancer. Radon gas can enter homes through any cracks in foundation walls, unfinished crawl spaces, gaps around pipes that enter the home, sump pumps and floor drains. Even new construction is not always without gaps, cracks, crevasses and crawl spaces. Radon gas permeates upwards from the ground much the way moisture or water vapor move and can seep through any openings.

How Does Radon Get into a Home or Building?

The air pressure inside a basement is generally higher than pressure in the soil surrounding the foundation of a home. The difference in pressure acts like a vacuum which draws air into the home through cracks, holes or openings in slabs and foundation walls, crawl spaces, floor joists, rim joists, pipes and electrical conduits, floor drains and sump pumps. Floor drains and sump pump openings can be a major source of radon infiltration into the home. Radon mitigation utilizes a vent pipe and fan systems to vent harmful radon gas out of the home. Spray foam, as well as polyurea, work to seal even the smallest cracks and crevasses to ensure that radon gas cannot seep into the home. This application ensures a more effective radon mitigation system.

Testing is the Only Reliable Means of Detecting Radon Gas

Testing is the only means of discovering whether or not radon gas is a problem in the home. Radon gas can accumulation when homes are not properly ventilated. Atmospheric conditions can affect how much radon gas is released into the air from day to day or month to month. Therefore, it is best to test for radon gas over a period of time to obtain an accurate reading. Be sure to hire a professional for any testing.

Radon Gas Mitigation Factors

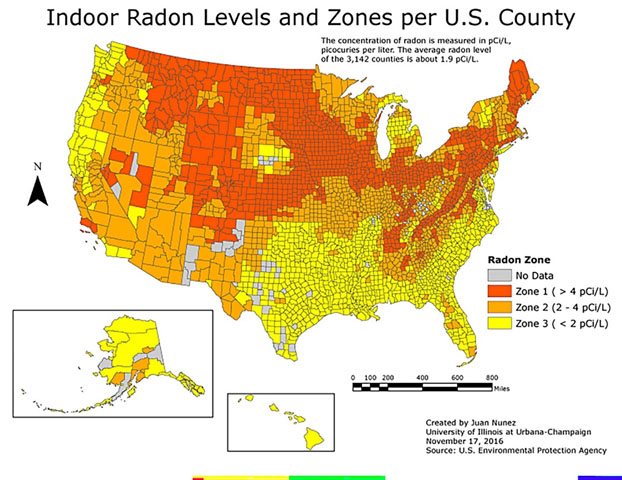

It is advised to hire a licensed professional to properly test for radon gas levels. Radon gas data on maps should be viewed as a generalization over a large area. Radon levels can vary within the areas shown. The following are considerations for deciding if radon gas mitigation is needed and the type of mitigation that will be most effective.

- The level of radon gas from testing

- The source(s) of the radon gas

- The structural integrity of the home or building

- Unfinished crawl spaces

- Ventilation routes

- Budget

Sealing, Ventilating or Both?

Mitigation using active or passive methods to reduce radon gas by venting it out of the home; however, it is important to seal gaps, cracks, crevasses and crawl spaces to create a more effective mitigation system. Even new construction can contain gaps, cracks and crevasses. Caulking is not usually a good fix, as it deteriorates over time, and it is still possible to miss leaky areas. Moreover, caulking will not provide a continuous membrane over a surface area. Using spray foam or polyurea will provide a monolithic, seamless membrane to seal the areas on which it is applied. In crawlspace homes, the ground floor can be covered in 4 inches of pea gravel, then covered with sheets of plastic, such as 10 mil polyethylene sheeting; however, there should be no cracks or openings between the plastic sheeting through which the gas can leak. The interior of the foundation walls can be insulated with spray foam which also seals all surface areas to which it is applied. This technique can be less labor intensive than installing insulation between the floor joists. Foundation vents and/or a vent pipe can also be used to divert radon gas outside the home. Since every home has its own unique set of circumstances, each must be evaluated individually to determine the best course of action.

Passive Radon-Resistant Construction Performance

A study conducted by the NABH Research Center in 1996, entitled, “Passive Radon-Resistant Construction Performance in Ventilated Crawl Space Homes” worked with homes builders in 6 states for 17 crawl space homes to gather data about ventilated crawl space homes. These homes were constructed in accordance with EPA recommended methods for radon-resistant construction. “Radon-resistant construction methods for crawl space homes essentially consist of a vent pipe (stack) installed from the crawl space floor through the roof. The bottom of the stack terminates in a tee fitting that rests on the crawl space floor, and the floor is completely covered with a vapor barrier that is sealed at the foundation walls, piers, and at seams. The sealed vapor barrier and vent stack (sealed under the vapor barrier) is designed to vent radon to the outdoors before it can enter a house,” NAHB Research Center, Inc., May,1996. Radon levels were taken before and after the radon-resistant construction method. Through this method, radon levels were lowered to recommended EPA levels.

Active Versus Passive Radon Gas Mitigation

Active and passive radon gas mitigation methods are most effective when the gas leaks are prevented or reduced from entering the home. While it may be necessary to vent radon gas out of the home, sealing gaps, cracks and crevasses helps ensure that more gas is not accumulating in the home. It is important not to use materials that deteriorate over time or materials that are put down in sheets. A continuous, monolithic membrane such as spray foam or polyurea is best.

Active Mitigation

Active radon gas mitigation systems entail a vent pipe that runs from the sub-slab of the basement to above the eave line of the roof. In some cases, the pipe can be routed into a garage attic. An electric vent fan is installed to move contaminated air. Some systems include a systems failure warning device. All areas of radon gas infiltration must be sealed. The EPA recommends that an active mitigation system be used if radon gas levels are at or above 4.0 pCi/L.

Passive Mitigation

A passive mitigation system is usually installed during the construction of a home. A passive system entails a vent pipe that runs from the sub-slab up to the eave of the roof and a physical barrier between the house foundation and the surrounding soil. This system is designed to provide a natural pressure differential and air current to direct radon gas away from the home. Again, sealing the foundation of the home will ensure against gas leakage.

Spray Foam or Polyurea--First Line of Defense Against Radon Gas

Spray foam is an insulation and a coating while polyurea is one of the most highly durable coatings available. Both types of applications work because they can seal large and small cracks, gaps and holes, providing a continuous, monolithic barrier that seals and protects as a first line of defense against radon gas. Both SPF and polyurea are excellent materials that also serve to improve the structural integrity of the surfaces in which they are applied.