PMC’s New High-Performance Xtreme Spray & Pour Gun

The ultimate purpose of innovation is to create positive change and value!

PMC’s Xtreme Spray & Pour Gun is designed for spray foam insulation and Polyurea Coating applications. It provides the user with unparalleled efficiency and substantial savings by eliminating down time and leveraging profits. The Xtreme Spray Gun has scratch-resistant parts for durability and savings, averaging $2,800-$3,500 per year over competitive brands.

Overview of PMC’s Xtreme Spray & Pour Gun

- Designed for both spray foam insulation and polyurea coating applications.

- Substantial savings

- Affordability–realize savings with each use.

- Reduces the cost of replacing parts. Fewer parts translate into faster, easier maintenance, virtually eliminating down time.

- Improved trigger reaction speed.

- Faster re-build time including re-buildable trigger assembly.

- New air cylinder design for improved efficiency.

- Diamond plate mixing chamber for longer-lasting durability.

- New check valve design to prevent material from entering the handle.

- Nine chamber sizes available.

- Innovative resin side seal last longer.

- Light-weight to reduce sprayer fatigue.

- Improved comfort: Ergonomically designed to fit comfortably in your hand.

- Increases efficiency and profits.

- Durable, long-lasting, scratch-resistant parts with a one-year warranty.

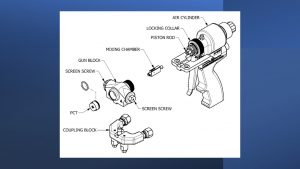

PMC’s Xtreme Spray & Pour Gun Technology

The air-purge system uses a trigger that channels air to one side or another of an air cylinder, actuating a mixing chamber triggering back-and-forth. The side seals press against the mixing chamber, creating a chemical seal. The mixing chamber, utilizing direct impingement, allows the chemical to mix and exit the gun. Virtually every other air-purge system introduced since 1974 is simply a subtle variation of the same basic principles and theme. Present-day air-purged gun components may look different; however, they still have the same functionality and design as the original concept.

- Spring-loaded Check Valve locks chemical out of the handle, eliminates material on the trigger assembly, prevents clogging of the ports in the handle, and the trigger can NOT get stuck in the open position.

- Enhanced Trigger Design provides a significant increase in performance and trigger consistency.

- Xtreme reliability: 60 plus sets sprayed with the same Diamond Plating Mixing Chamber and Engineered Resin Side Seal Set!

PMC’s Quality Assurance:

PMC backs its high-quality spray equipment, which is manufactured, assembled, and tested at its factory in Lakewood, New Jersey, USA. Every piece of spray equipment and plural component SPF insulation and coating spray guns are created on-shore and made in the USA. All of PMC’s equipment and spray foam guns are tested at its New Jersey, USA facility.

Discover the PMC Xtreme Difference today!

Download Our Brochure

For More Information: