The Blame Game and What’s Really Going On

What I often hear about our industry’s current shortages, and price increases, is “This is someone’s fault, and they’re going to pay”. “This is all a plot to put the little guy out of business”. “Somebody’s making a lot of money”. These statements have all been spoken, or at least thought of, over the past few months by just about every contractor in the spray foam industry.

It’s understandable that people feel a need to vent their frustrations. Blaming the manufacturers, and other industry entities, for our industry’s current dilemma is misguided. Here’s why: I’ve worked for years in leadership roles in some of the biggest manufacturers and raw material suppliers in our industry, and I can say with absolute truth that these organizations are run by people, just like you and I. In the 40 plus years I have been in the industry, I have never been a part of, nor have I ever heard of some stairwell discussion, to “stick it to the contractor ”. Pricing decisions are painful, and they are a result of unacceptable cost increases put on manufacturers by the raw material suppliers. Just like your price increases to your customers, they are reactive, not proactive.

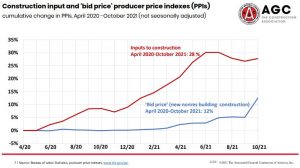

The construction industry was hit hard with Covid issues, labor issues, mother nature, off-shore supply chain issues and domestic transportation issues – across the board, not just spray foam contractors. Here are some of the other products which were hit hard: The price of steel (think steel studs, steel resin and Iso drums, fasteners, and panels) has gone up 142 percent since October 2020! Softwood lumber prices have increased over 100% at its peak and is currently 80% higher than 2020’s average price. Shipping costs from China (ship-board containers of raw materials) have increased 500%. A lot of key components to make resin (flame retardants and catalysts) come from China. The manufactures started to buy raw materials from China years ago to keep resin costs down. The cost of plastic resins (not including polyurethane foam resin) in general have more than doubled in 15 months. PVC and cPVC for residential water lines has more than doubled – and the US is the world’s largest exporter of PVC. The cost of polyethylene vapor barrier and membranes have more than doubled since June of 2020.

It appears that construction continues to be a more reluctant to pass on increases to its customers. Either the contracts did not include a cost escalator clause, or we didn’t “feel” the pinch. Whatever the reason, we paid more on the cost side and didn’t recover the increase on the revenue side. That’s not a place anyone wants to be.

Now, we can all speculate what the cost of our SPF systems will do when the dust settles. Keep in mind, however, that the consumer knows that spray foam is the best, most valuable insulation money can buy, and the demand is still high for our product. Our competition is not the spray foamer down the road – it’s the other types of insulation – and they are high-priced as well. See you at SPFA 2022 in San Antonio and the end of the month.