Choosing an SPF System

What to Know Before You Buy SPF Material

Before making your next purchasing decision, lets confirm a few things. Contractors purchase raw materials at a cost, and this “cost” has two components, risk and benefit. We try to maximize benefit and minimize risk. A few years ago, the overwhelming benefit to some brands was that it was available – and that was about it. Those days are gone, and once again U.S. based foam material is readily availability.

Know Your Risk Assessment

When determining risk associated with your “brand of choice” there are a number of factors to consider. The questions are:

- Is the brand allowed to be sold in the U.S. and should I be using this material? Just because it’s available doesn’t mean its allowed.

- Does the material have the proper testing and approvals?

How Do I Know if the Foam is in Compliance?

Please refer to the SPFA document hosted on the Code Compliance Page. Code Compliance webpage

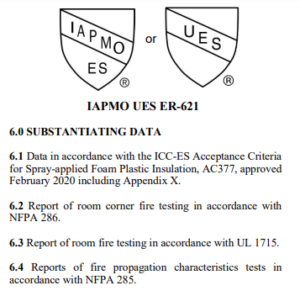

In order for a spray foam resin and isocyanate to be sold in the U.S., the finished foam must be tested for two critical characteristics, fire performance (flame spread) and thermal conductivity (R-value). The fire performance is determined in accordance with ASTM E84 and UL 723, commonly referred to as Flame Spread tests. If the product will be installed at an installed thickness greater than 4 inches the foam must be tested in accordance with NFPA 286. If the product will be installed in attics and crawlspaces without a prescriptive thermal barrier, then further testing and evaluations are required. Many off-shore products do not have the required testing and thereby increase the contractors risk. If the contractor cannot provide the appropriate testing documents or evaluations, the contractor may be required to remove the product.

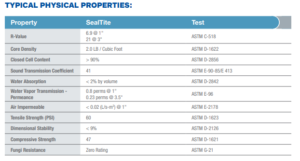

Lets look at a typical Technical Data Sheet from a North American SPF resin manufacturer. Most manufacturers state both Aged R-value (an FTC requirement) and Fire Performance as determined by independent third party testing labs and, most importantly, an independent code compliance evaluation.

Each manufacturer displays the data differently. Please take the time to read the TDS completely and read the compliance report carefully. The code compliance report identifies the specific sections and applications the foam can be used, the specific foam name (brand, tradename) and manufacturer.

Here is an excerpt from a leading SPF system manufacturer. Note the use of “Aged Thermal Conductivity” reporting taken directly from the third party product evaluation conducted by IAPMO. This manufacturer provides the code compliance documentation under separate cover and the fire testing in a separate section of the TDS.

Courtesy of Carlisle Spray Foam Insulation

Foam Must be Tested & Evaluated to be Approved

In the U.S., the finished foam insulation must be tested by an accredited third party for its insulation effectiveness. We use ASTM C518 or C177 to determine the R-value. The FTC (federal Trade Commission) requires this test to be conducted on “aged”

samples which represent the insulation performance of 15 year old foam. The material is “aged” under specific controlled conditions at the third party lab and retested using the C518 or C177 test method. Many off-shore manufacturers do not provide the aged R-value testing result.

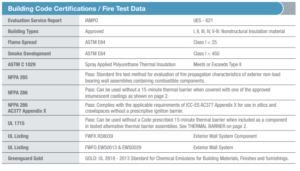

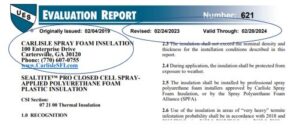

The physical properties of the finished foam must be evaluated by an independent third party. There are a small number of groups authorized to evaluate our products, one of which is ICCES (International Code Compliance – Evaluation Services). A manufacturer submits the third party test results to the evaluation service and an evaluation is provided – commonly referred to as an ESR – Evaluation Service Report. You, the contractor assumes the risk associated with installing a material which does not have an independent Evaluation Report.

The Code Complaisance Report is very specific – this specific material, manufactured by this company, can be used for these specific purposes.

*If contractors are using a foam product which does not have a current (note the dates of issue and renewal) Code Compliance Report, the contractor is accepting considerable risk.

Courtesy of Carlisle Spray Foam Insulation

Does the manufacturer provide the required documentations?

There are a number of critical documents the manufacturer of the resin and isocyanate must make available to you, they include the Safety Data Sheet (SDS) which provides information regarding the chemical components of the resin and isocyanate. When these chemicals are transported or consumed (used) the SDS’s must be available to the transport company, on your tuck and available to your applicators during installation. The product label on the container is also required to provide specific information including date of manufacture, place of manufacture, net weight, name and address of the manufacturer and product name. If the product carries certain certifications, these agencies will also have a labeling requirement. These additional requirements must be known and understood – as the purchaser of the material, you are accepting all responsibility for the material at the time of purchase – providing the necesary information is now your responsibility.

The product Technical Data Sheet must be made available by the resin manufacturer. The TDS contains vital information regarding the suitability of the specific product for the intended application. It is the contractors responsibility to confirm the resin, isocyanate and finished foam meet the requirements of local code officials, state and local I-codes and the material has been thoroughly tested using U.S. compliant test methods. Remember – it you buy it, you are in effect, acknowledging the product meets all applicable regulations. The regulations include, Dept. of Transportation, EPA, OSHA, FTC and I-codes.

Reconsider Your Purchase:

The resin manufacturer cannot provide the necessary documentation, certifications and approvals to meet your satisfaction as the purchaser, as the liability you are about to take on by installing the product, is not worth the risk.

Does the Manufacturer Provide Support?

Once you purchase the material, there are a number of situations that may need the support of the manufacturer, such as:

- Transportation issues

- Code official questions

- Homeowner questions and other requests for information

What Happens If…

- You just can’t get the foam to process well?

- The manufacturer doesn’t have local field tech reps.

- Isn’t located in the same country

If you find you can’t process the material, who will take it back? Who will exchange it? How do you get your money back from an off-shore manufacturer?

Remember, the choice is yours…….