We received many positive responses to our previous article entitled, “A Tribute to Early SPF Pioneers”, so we thought we would share more interesting stories. We want to thank folks for stepping up to help us all remember, and learn about, the early SPF days. Be sure to read all three stories. The last story, while hilariously funny, is also packed with great learning opportunities. We bet our audience will relate. Special thanks to everyone who interviewed with Spray Foam Insider. You guys have our ut-most respect!

Keith Ibbitson, 19 years SPF. Lead Insulation and Ops Manager for Callrich Eco Services & Air Seal Insulators,

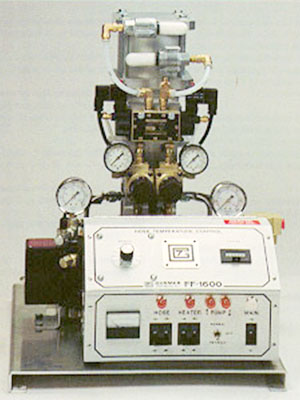

Toronto, Ontario, Canada, shares his photos of an FF1600 Gusmer and an early Glas-craft.

“Those early guys were the real pioneers, and it was their dedication that helped us develop the industry standards we have today. I have a tremendous respect for all of them, “said Keith.

“I love this industry, but it was hard back then. I saw many workers come and go, but I stuck with it and worked my way up the ladder. The company recognized my dedication, took me under their wing and trained me well. Today, I am the company’s Lead Insulator”. Keith began working with a Gusmer FF1600 which was an air-driven unit. He thought the equipment was too old to do the job, but after using it, he was surprised to find that it performed like a workhorse! Keith also used a Glasscraft mh3, which was used for both polyurethane and polyurea coatings. He felt that it too was a pretty good workhorse.

Keith has always maintained a keen interest in SPF history. Much of his off-time has been spent researching everything about the history of industry. Keith explains, “Back in the 1960’s, applicators wore gloves and paper filter masks. They didn’t have all the PPE gear and equipment that we have today. I’ve watched the industry change by leaps and bounds over the years.” Keith’s words of advice for those who want to get started in SPF is to “…get as much training as possible because down time and accidents can be very costly. Also, being able to trouble-shoot equipment accurately can make or break a business.”

“My First Spray Rig Came to me In a Box!”

“I could see the potential in SPF,” says Larry Molitor of Molitor Enterprises, Huntsville, Texas.

Larry Molitor started in the spray foam business in 1980. “My first rig came to me in a box! It was two weeks before the sales rep showed up to help me, but I was done assembling it by that time”, says Larry. Larry explained that back in the early 1980’s, it was hard to get professional assistance in Huntsville, Texas. There were no equipment dealers or training near him at that time, so he had to learn as much as he could on his own. “I learned some hard, expensive lessons, but I kept going because I could see the potential of staying with it. You could make a few mistakes then and fix them. If you stumble today, you’re done,” said Larry.

Putting out as much foam as 10,000 square feet per day, Larry had to find a way to keep up his demanding pace. An equipment rep helped Larry develop a special pump, using a 45:1 King air motor, to increase his output. It worked! “There’s not another roofing system today with a return on investment like spray foam. My customers report that their energy bills have been cut by 40% or more. They’re realizing significant saving over 2 1/2 to 4 years of the application. And, I’ve never heard a bad word from any of my customers.”

Bill Winter Remembers The Run-Away Spray Gun and Other Crazy Moments

Bill Winter, President of Blue Diamond Builders and Blue Diamond Spray Foam

Bill Winter, President of Blue Diamond Builders and Blue Diamond Spray Foam, in Trinidad, Colorado remembers what it was like to get started in the SPF industry back in 2003. Luckily, he had a mentor to show him the ropes, but it was not without incident and a lot of learning through the school of hard knocks. “ I was in real estate at the time, and a friend of mine took me on an 18,000 sq ft roof he was in the process of spraying. He had 4000 ft left to do when I came aboard. We were up on the highest roof deck and had to go down the ladder to get to the lower roof deck. My mentor handed me an aluminum ladder to climb down to the lower roof. As I took hold of the ladder to climb down, I felt a sudden shock of electricity hit me hard. It was static electricity build-up. Lesson number one: Watch out for static charge. This would be the first of a long line of lessons I would encounter,” said Bill.

Bill started out by dragging hoses for his mentor. Unfortunately, his mentor neglected to tell him about over-spray. Wearing only street clothes, Bill kept up as best he could, dragging hoses until 8:00 PM that evening. It was then that Bill realized that he looked, and felt like, a piece of fried chicken. His skin and hair were covered in droplets of foam, and his clothes were as stiff as a board. Add a good case of sun burn to that and you have a pretty good idea how uncomfortable Bill was, but he was not dissuaded and stuck with it like a champ!

Another time, while Bill was doing “on-the-job roof training”, he watched in horror as a wide sweep of spray foam went over the 3-story roof top and onto a woman walking on the street below. She took a pretty good hit of spray foam, as her glasses, hair and clothes were peppered with tiny droplets of foam. One of the sprayers ran down 3 flights of stairs to catch her and ask if she was okay. Stangely enough, the woman kept going, ignoring his pleas to help her and make things right. They never saw or heard from the woman again.

Bill’s mentor had a used Gusmer 2000 and a D-gun, so that’s what Bill trained on. Later, he used an air purge gun. For some reason, the spray gun became stuck in a wide open position and no one could figure out how to re-adjust it. Shutting it off caused the gun to have a cross over so severe that material filled the gun clear down into the handle. With 900 sq. ft. of roof left to spray, Bill’s mentor finished the job with the spray gun running wide open at full blast. His mentor somehow pulled it off, and the roof looked great. “That’s the thing, when you watch someone who is experienced spray foam, it can look deceptively easy until you try it yourself. Learning to spray foam is like someone learning to drive in snow for the first time. It takes time to get your barrings and learn how it’s done,” said Bill.

“Another thing I didn’t realize at the time was how black my hands would get when I started spraying. I tried everything to get the black stains off. A little of it scrubbed off in the shower, but the rest had to wear off over time The first time it happened, I had to attend a big family gathering that same evening. So, I kept my hands in my pockets the whole time. I went to the school of hard knocks, that’s for sure, but I stuck with it and kept learning from my mistakes. Today, I can look back and laugh, but it wasn’t all that funny at the time. Bill’s advice to new SPF contractors is to get as much proper training as possible to avoid the headaches.

Thanks You to Those Who Have Shared Their Photos:

Early FF1600 Courtesy of Jessee Chavira

of Central Coating Company

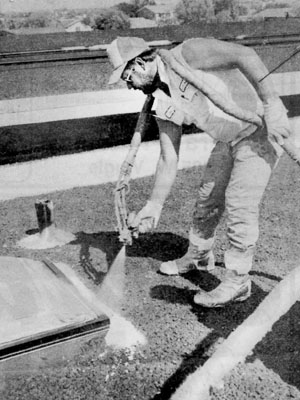

Early Glas-Craft Maxi, 1962 Courtesy of Kieth Ibbitson

A big thanks to those who shared their stories and photos. If others learn from these guys, they have a good chance of making a success of their careers.