Spray foaming roofs can be tricky when overspray is a concern. Hundreds of vehicles, along with the surface on which they are parked, can be affected by overspray as gravity and wind move the residual spray foam through the air to the ground below. Sometimes, moving dozens of vehicles from the perimeter of a building is just not a practical option. Moreover, wind direction and gusts can be unpredictable. It is important to understand that spray foam stays in its molecular form until it reaches a surface on which to cure. Once cured, it is a daunting task to remove it from vehicles and paved surfaces. Building a simple spray booth will make the job go quickly and smoothly saving thousands of dollars as well as insurance headaches from cleaning vehicles or paying for new paint jobs.

Constructing the Spray Booth

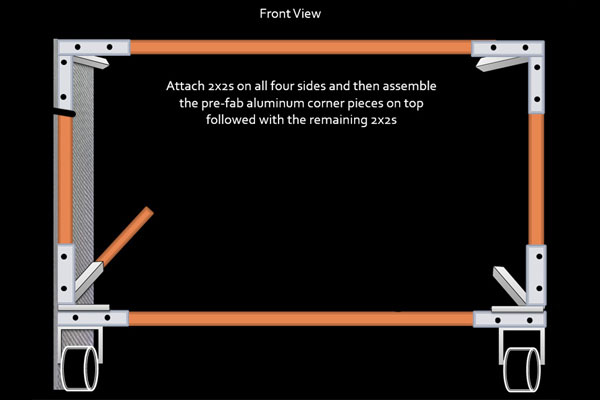

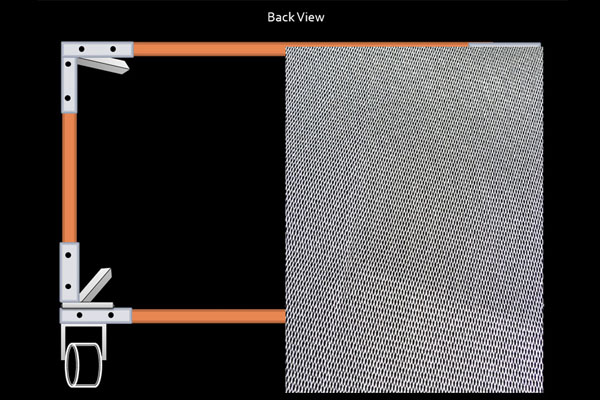

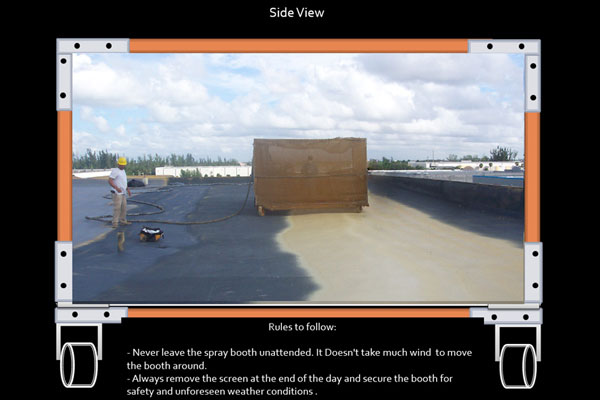

The spray booth is mobile and essentially a cube, with three enclosed sides plus the top. The bottom is completely open for spray application. It is designed to contain the overspray as the cube is moved forward. Be sure to lift the front screen to allow the foam to expand. Then, move forward for the next application. The applicator should wear all proper PPE during the spray process.

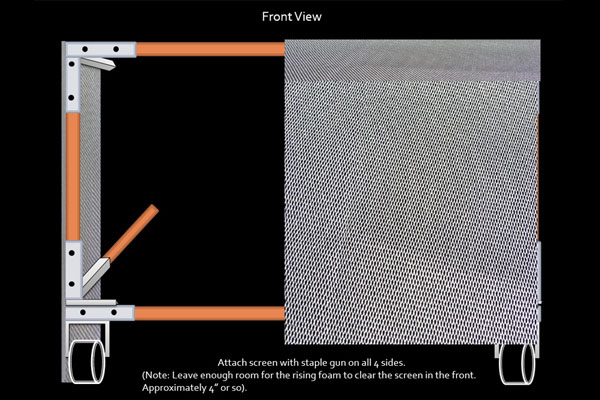

This Spray Booth is covered with burlap; however, house screen can also be used.

Be sure to lift the front screen after spraying to allow the spray foam to expand as you move to the next area to be sprayed.

Here are the Parts You Will Need:

Material List:

- 2”x2” Aluminum Tube Steel

- 8’x8”x1/4” Aluminum Plate

- 2”x2” x 8ft lumber

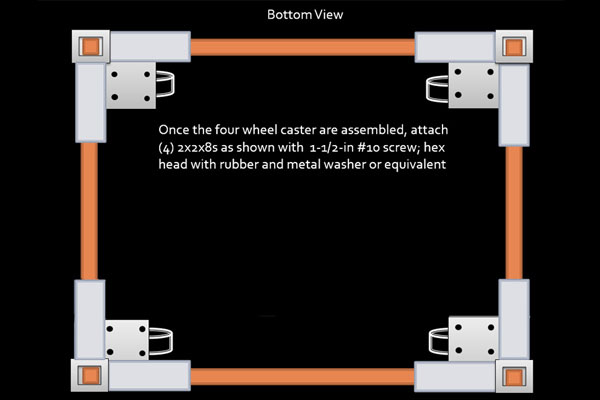

- 1-1/2-in #10 screw; hex head with rubber and metal washer

- (2) Caster Wheels (non swivel)

- (2) Caster Wheels (swivel)

- 3/8-in x 2-in Standard Hex Tap Bolts

- 3/8-in Coated Standard Hex Nuts

- 3/8-in x 1-in Standard Flat Washers

- Roll of burlap or house screen

Assembly tool List:

- Hamer staple gun

- Cordless drill

- #10 hex head driver

- 3/8” hex head driver

- 3/8” wrench

- 3/8” ratchet

How to Assemble the Spray Booth

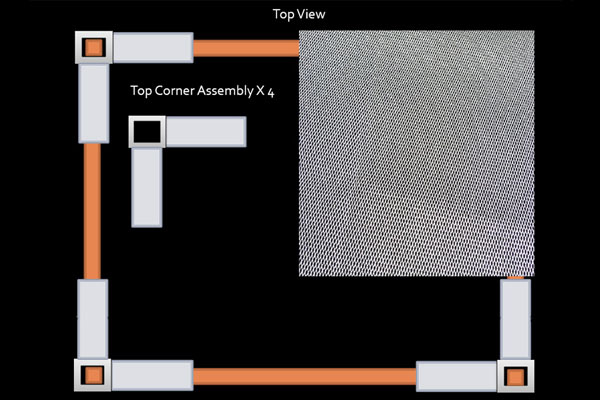

- Cut 24 pieces of 2”x2” Aluminum tube steel approximately 18” long

- Cut 4 pieces of 8’x8”x1/4” Aluminum Plate

- Weld assemblies as shown

- Pre-drill holes for the wheel casters

- Pre-drill holes for 2x2s

What to do if Overspray Occurs?

Using a spray booth is your best line of defense to prevent overspray. Used properly, it should work like a charm. In the event overspray occurs, clean it from the vehicles immediately, especially the windows. A sharp scraping tool can be used gingerly on the windows. Leaving foam on windows can result in producing a glare, once vehicle owners use their whippers over the foam. This glare could impair visibility resulting in accidents. Who wants to be responsible for that? Once foam has cured on a vehicle’s painted areas, there are few products that can remove it properly. Car detailers use a product call, “Clay Magic”; however, a great deal of rubbing is often required to remove the foam completely.

The Bottom Line

The bottom line is to eliminate the potential for overspray before you begin your jobs. Use a spray booth, get on with the job and make your customer happy. After all, you want to look professional, satisfy your customer, obtain a positive reference to add to your portfolio and get invited back again for additional projects.