The blower door test takes the guess work out of detecting air leaks in a structure; however, most contractors would like to pass the blower door test the first time. It is estimated that 50% of newly constructed homes will fail the blower door or air-tightness test. Most blower door test failures occur because of a lack of understanding of what is necessary to create a continuous air barrier system. If you want to pass the blower door test, most experts recommend brushing up on air barrier performance requirements and air sealing techniques. A word of caution: To bone up on building science, make sure you read material that is written by experts rather than relying on articles at random on the Internet. Reading the first article you find could contain misleading information that is written by persons who are not well informed. The ABAA is a good resource for information.

Testing Building Envelope Air-Tightness with the Blower Door

Source: Wikipedia

A blower door is a machine that is used to depressurize/pressurize a home or building. It is used to detect air leakage pathways and measure the air-tightness or air flow of the building envelope. A Duct Blaster is used to test ductwork and detect air leakage locations within a structure. It has been more commonly used in residential settings; however, the blower door is fast-becoming a must-have tool in the commercial market. In fact, the General Services Administration (GSA) compliance regulations require that new US federal buildings be tested for air tightness as part of its effort to reduce energy costs and energy consumption.

The blower door has variable speed fan to induce a range of airflows in order to pressurize or depressurize most any size building or structure. A manometer (a pressure gauge) is used to measure both the pressure differential that flows across the face of the fan and across the building envelope to detect air flow. A mounting system holds the door in place for testing.

How it Works

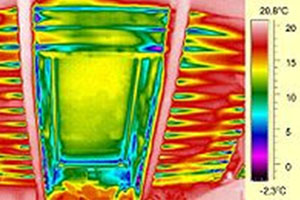

The built-in fan blows air into or out of a home or building to create either a positive or negative pressure difference between the inside and the outside of the structure. This pressure difference is typically 50Pa or 1.57 psi for a standard blower door test. The process is based upon the principle that the tighter the building, the less air is needed from the blower fan to create a change in building pressure. Traditionally, a depressurization test is conducted; however, performing both pressurization and a depressurization test is preferable. Testing can be accomplished by operating the blower door manually or with the aid of data acquisition and fan control software. The speed of the fan, in cubic feet of air per minute to hold a 50 Pa pressure difference, is recorded the CFM50 value. Alternately, this number can be divided by the air volume of the building to get the number of air changes per hour, recorded as the ACH50 value. The blower door, in combination with an infrared camera, can be used to pinpoint the sources of air leakage, as shown in the IR-camera photo of a window during a blower door test. There is a standard test procedure for blower door testing: ANSI/RESNET ICC-380 2016.

Source: Wikipedia

Main Causes of Blower Door Test Failures

Source: Today’s Home Owner

Source: Woodsun.com

Source: Elcodaily.com

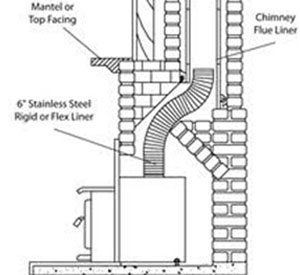

Blower door tests failures often occur because unsealed envelope penetrations, such as bath fans, sprinkler heads, light fixtures, and fireplace inserts, create air leakage paths to the outside of the building. Bath fans have an exhaust with back flow prevention device, but sometimes it’s missing when installed. This allows air to flow in to the home. Sprinkler pipes and ceiling lights in attics are often not properly air-sealed, so these are other ways air can leak in. Fireplace inserts are often installed without being properly air-sealed. When and where permitted, it is helpful to place caps over ceiling fan vents to reduce or eliminate air flow during testing.

Electrical and Plumbing Changes Often Occur After Insulation and Air-Sealing

Photo by Guilherme Cunha on Upspash

Another concern is that trades persons are often called back to the job site to perform tasks after the home has been insulated and sealed, such as when home or building-owners want changes. Trades persons must then cut into areas that have been insulated or sealed to make changes to such things as electric and plumbing. Every hole that is drilled, every cut or disturbance to the structure can affect the flow of air in the home. Air leaks can persist if these disturbed areas are not properly attended to and may contribute to a failed blower door test.

Anticipate Potential Air Leaks Ahead of Time

Those who consistently pass the blower door test have learned to anticipate where air leaks are likely to occur and understand how to trouble-shoot them ahead of time. Air leaks can occur where two different materials meet. It’s important to inspect a structure inside and out. For the exterior, examine exterior corners, water faucets, where the siding meets the chimney and where the foundation and where the bottom of exterior brick and siding meet. On the interior, check switch plates, electrical outlets, gas and electric service entrances, sink vents, ductwork, door and window frames, (including weather stripping), baseboards, fireplace dampers, attic hatches, around wall or window-mount sir conditioners, phone and cable TV lines, vents, sky lights and fans and where dryer vents pass through the wall. Placing caps over vents (where permitted during the test) will help ensure passing the test.

Every trade involved in the construction of homes needs to understand air barrier principles that make the envelope a sealed and effective thermal boundary. When a blower door test failure occurs, it is too often the insulators that bear the responsibility of fixing the problem. Another contributing factor is that there is often a great deal of turnover in trades personnel making it difficult to ensure that everyone is properly trained. Having a coordinated effort among those involved in the project, along with a strong commitment and building science knowledge is the best way to achieve an air-tight structure and pass the blower door test.

For more information about Blower Door testing, visit: greenbuildingadvisor.com/blogs/dept/musings/blower-door-basics

Article Contributor: Richard S. Duncan, Ph.D., P.E., Technical Director Spray Polyurethane Foam Alliance. Email: rickduncan@sprayfoam.org