Mason Knowles (center) with one of his SPF Roofing Class in Mumbi, India, 2013

30 years ago, the majority of spray foam applications involved roofing. Now, building envelope insulation takes the lion’s share of the business. With stiff competition, particularly in the spray foam insulation markets, a few insulation companies are branching out into spray foam roofing. It is important to recognize that an applicator trained in SPF residential insulation would not be qualified to install a SPF roofing system.

I always encourage contractors to seek out other spray foam markets where there might be less competition and better margins. But, we don’t want the new spray foam roofing contractors to experience the same failures as the pioneers 40-50 years ago. Outside of cold storage applications, spray foam roofing may require the largest learning curve to learn how to do it right and the largest potential for liability if you get it wrong.

Background Information:

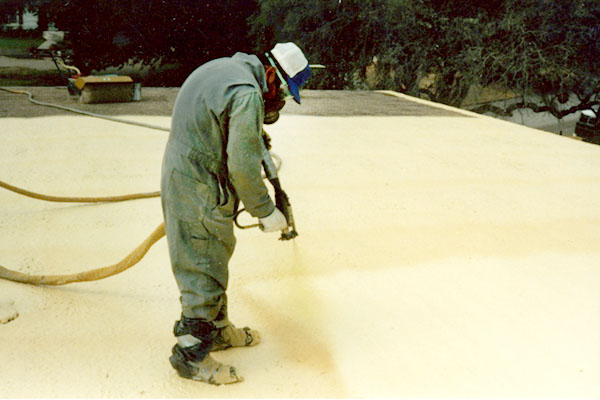

SPF roof training in Umpqua, Oregon, 1985

Spray polyurethane foam was first used commercially in the early to mid1960’s for cold storage and industrial insulation projects. Because the material is water resistant, some of the pioneer contractors experimented with applying the systems on roofs. The mid 1970’s saw application and substrate preparation techniques that led to today's standards. The foam roofing industry experienced growing pains in two ways during its early years of use. First, although the contractors developed a high skill level in spray foam insulation application, they did not necessarily have knowledge of or skills in roofing. Some of the early premature installation failures are attributable to incorrect roofing details and techniques. Secondly, many traditional roofing contractors entered the spray polyurethane foam roofing market in the early 1970’s to take advantage of the energy saving characteristics of spray polyurethane foam. Some of these contractors had insufficient training and knowledge that led to premature failure of the roofing systems they applied.

Over the last 45 years I have trained more than a thousand applicators in the art of spraying polyurethane foam roofs all over the Unites States--from coast to coast, the Caribbean, Mexico and even India. From that experience, I have learned that the training provided to the applicator must be specific to the applications the contractor is expected to perform.

What is required for an existing spray foam insulation contractor to get into the SPF roofing business?

- Understanding limitations of weather and how much can be accomplished annually

- New equipment

- Training in SPF roofing application

- Training in roofing practices and principles

- Experience

Weather Limitations:

SPF roofing is dependent on the weather cooperating. Unlike interior applications where we can heat, cool and even dehumidify the space in order to install spray foam, you cannot control rain, snow, wind, and cold or extremely hot temperatures on a roof. Before getting into the roofing business you need to determine how many days, and how many hours of the day, someone can spray foam and coatings without getting into trouble.

For example, when I ran a spray foam contracting business in Houston, Texas in the 90’s, I determined that we could effectively spray foam 200 days of the year for an average of 5-6 hours a day. Our most common issues involved rain and wind. In northern climates, snow and cold temperatures are the main concerns and can shut the season down for months at a time.

Consider also, that a typical roof requires a lot more foam and coating than a typical residential insulation project. Most medium size houses can be sprayed with a couple of sets of foam and approximately 100 gallons of fire retardant coating. A medium size roof of 20,000 sq. ft., on the other hand, would require approximately 15 sets of foam and 1500 gallons of coating.

Equipment:

Due to weather limitations and the increased volume of foam and coatings that spray foam roofing entails, it is important to be able to install as much foam per day as possible. The more foam and coating that can be applied in one day the better the potential for profit. In order to be in a position to make decent profits in the spray foam roofing market, you should strive to spray 4-6 sets of foam a day and to basecoat what was sprayed that same day.

In order to obtain this volume of daily production, you need larger capacity proportioner and coating equipment. Most spray foam roofers use a 40/lb. a minute proportioner. The larger proportioner may require a larger generator as well. A 50 KW unit is typical for a hydraulic or electric powered proportioner. With this equipment, an applicator has the potential of installing up to 8,000 ft. a day of spray foam to full thickness (2-inch average/typically) and coat it with any of the 3 generic types of roof coatings (acrylic, silicone, polyurethane) typically used in spray foam roofing.

Along with a larger proportioner, the spray foam roofer requires additional equipment specific to roofing including; compressors, generator, coating equipment, ladders, fall protection equipment, wind screens, skylight covers, roof cleaning equipment, debris removal chutes, foam trimming equipment and more. (see side bar for specific list of roof equipment).

Most of this equipment would not be part of a typical spray foam insulator’s inventory.

Estimated Equipment Start Up Cost: $120,000 - $130,000

Spray Foam Roof Training:

With proper training, new applicators can spray smooth uniform foam.

This job was sprayed by a new applicator 7 days after hands-on training

Most of the major spray foam suppliers offer a basic SPF training, but not all provide training to installing spray foam roofing.

A good training course for the beginning applicator of SPF roofing systems requires at least 5 -10 days of training whereas a residential contractor may acquire needed skills in 3-5 days. A lot will depend on the learning curve of the individuals being trained and the complexity of the projects that the contractor will be bidding.

A good training course will include the following:

- Basic equipment set-up

- Maintenance

- Troubleshooting

- Spray technique

- Shipping and handling and disposal of materials

- Safety and health when using the materials

From there, the training becomes more specific to the application and includes:

- Building codes and regulatory information

- Job specific safety procedures

- Job specific guidelines on application, substrate preparation, etc.

- Use of additional equipment required for the job (ladders, scaffolding, coating, masking & trimming tools, compressors, generators, etc)

- Inspection and quality control procedures

- Roofing application specific education (such flashing details for roofing)

After obtaining basic spray foam roof training, it normally takes 6 months to a year for an applicator to become proficient. It is important during this critical learning stage that the applicator have a knowledgeable and experienced technician available for support. Much of this technical support can be accomplished over the phone.

Estimated Spray Foam Roof Training Cost for 3 employees: $25,000

See Side Bar: Spray Foam Roof Training

Equipment Recommended for Spray Foam Roofing

| Equipment | Description | Avg. Cost |

|---|---|---|

| Equipment trailer | 16-20 ft. tandem axle | $10,000 |

| Spray foam proportioner | 40 lb./minute | $27,000 |

| Generator | 50 KW | $30,000 |

| Spray foam hoses | 300 ft 3/8” (plus 10ft. 1/4“whip hose) | $5,000 |

| Spray foam guns | 2 ea. GX7 or equivalent | $7,000 |

| Transfer pumps/ hoses | 2 ea. 2 to 1 capacity w/ 12 ft transfer hoses | $3,000 |

| Foam trimming tools | ||

| Power roof scarfer | $3,500 | |

| Hand held trimming tool (air operated) | $1,600 | |

| Roof cleaning tools | ||

| Power broom | $3,400 | |

| Power washer | $600 | |

| Power spudder | $3,700 | |

| Assorted brooms, spud bars, etc. | $600 | |

| Trash debris chutes 10 ft long, 6 ea. | $600 | |

| Back pack air blowers 3 ea. | $1,000 | |

| Safety equipment (specific to SPF roofing) | ||

| Fall protection roof anchors and harnesses | $6,500 | |

| Warning line system | $2,500 | |

| Skylight covers $500 ea. 6 total | $3,000 | |

| Coating equipment | ||

| Coating pump, 45 to 1 (gas powered*) | $12,500 | |

| Coating hose 5,000 lb. pressure rated 300 ft. | $2,500 | |

| Transfer pump with hose, 5 to 1 | $1,000 | |

| Coating spray guns Graco silver gun with 35mm tip or equivalent 2 ea. | $700 | |

| Spare parts kit | Foam and coating | $3,500 |

| Total | $128,700 |

* Note: Air powered coating pumps can be used also at a lower cost, but would require a minimum 80-100 CFM air compressor, which would be considerably more expensive.

SPFA Certification Program:

SPFA's Accreditation Program started in 1987 with the goal and mission of providing both classroom and hands on education and training in different SPF applications. SPFA offered accreditation for applicators and inspectors in roofing or building envelope applications. In 2012, SPFA changed to an ISO certification program where an individual can be certified as an assistant, installer, master installer, and project manager or field examiner. I would recommend that any spray foam applicator that wants to get into the roofing markets take all of the courses up to and including master installer and project manager.

The courses are developed and reviewed annually by the Certification Committees and managed by a third-party certification team. The Committee consists of volunteers from a varied cross section of the sprayfoam industry and includes; inspectors, contractors, foam & coating suppliers, chemical producers, equipment manufacturers, distributors and more.

Supplier Courses:

Most spray foam material manufacturers and distributors offer some sort of training. I would avoid the short 1 to 3-day courses in favor of a longer more specific course. Some suppliers offer a training program specific to spray foam roofing and also offer SPFA’s certification course curriculum. These courses are typically held at the supplier’s facility although some may offer onsite training at an additional charge.

Third Party Consultant Courses:

A few spray foam consultants offer their own spray foam courses that can be similar to the supplier’s courses with some added content For example, my training includes, SPFA course curriculum, hands on onsite training plus presentations on a variety of topics developed over the last 25 years such as, sales and marketing, developing new territories, product liability, codes and regulatory issues, OSHA safety, working commercial jobs, cold weather applications, trouble shooting projects, quality control and much more.

What Can Go Wrong?

Foam degrades from UV and will cause adhesion problems

Coating delaminating from foam due to UV exposure

Interlaminar foam blister from spraying thin passes over UV degraded foam

Thin coating leading to UV degraded foam

Spray foam roofing applications have similar liability issues as residential or commercial applications, such as foam contraction, adhesion, odor issues, thickness disagreements, code issues etc. But they also have many potential liabilities that an insulation contractor doesn’t need to worry about.

Things that a Spray Foam Roofer can get Wrong:

Standing Water:

Building codes require that new roofing systems have a 1/4-inch slope per foot. Retrofit applications (over existing roof coverings) allow roofs that have positive draining. While spray foam roofing systems can easily handle small puddles of water after a rain, standing water that sits for months at time can negatively affect the coating.

It’s really not all that hard to get water to drain off an SPF roof. First, bid the job so that drainage is figured into the costs. You don’t necessarily have to add tons of foam. You may be able to add drains, cut or groove drainage channels or mechanically fasten a tapered board system first. These systems don’t cost as much as you might think, and SPF adheres to most of them very well.

Non-Uniform, Ugly Foam:

Ugly, non-uniform foam can cause excessive ponding and use 30% to 50% more coating

Most spray foam that I see in residential insulation would not be smooth and uniform enough for spray foam roofing. It is very important to have as smooth and uniform surface as possible in spray foam roofing. You need a uniform surface to have water drain properly. The roughest surface profile that is acceptable for a spray foam roof is verge of popcorn. Verge of popcorn can take 30 to 50% more coating to cover than a orange peels surface. A lot of money is lost on coating over rough surface profiles.

Where you get really ugly foam is in the hard-to-reach areas and places you have to get real close to, such as drains, gutters, edge flashings, pipes, curbs, under air conditioners, etc. It doesn’t take a lot of work to trim the lumps and smooth the job with more foam. Remember, each job is your signature and resume. Most building owners expect a job that looks like the brochure you hand them. If the job looks like a bumpy dirt road, you can be sure they will have concerns about your performance and quality of workmanship.

Flashing Detail:

Poor flashing detail plus deteriorated fascia led to leaks on this roof. Flashing should have been installed on the edge and the deteriorated fascia replaced before installing the foam.

Edge detail done correctly

Most spray foam roofing leaks occur due to incorrect flashing. Gutters, drains, parapets, edge details are very important. Learn the roofing principles of flashing properly and follow them. Don’t listen the spray foamer who say, “Nine times out of ten this detail works”. I hate to hear a contractor justify a problem with this line. Never use the detail that fails 10% of the time. That’s like saying your brakes work nine times out of ten. You end up spending twice as much time and money fixing the problem than you would have if you had bitten the bullet and used that very reliable, albeit more time consuming and expensive flashing detail, on the other nine jobs. Use the most proven method each time or DON’T DO THE JOB!

The Magic Foam Theory:

Foam everything??? This applicator hoped covering everything with foam

would stop the leaks. However, he was wrong, poor detail work

and incorrect flashing caused roof leaks in this area.

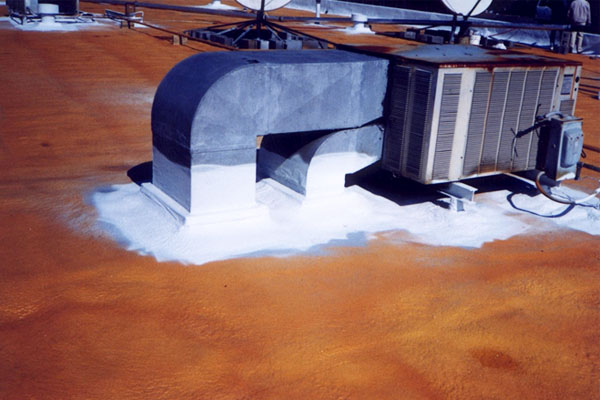

Raise the HVAC equipment, the electrical lines and gas pipes place them on stands

All prospective foam roof systems require an analysis of the roof assembly. This includes a moisture survey of the existing assembly and core cuts to determine if the sub assemblies are in good condition. Why spend time and money on a good roof survey to evaluate the substrate and moisture in a roof? Just spray SPF over it and it will be OK. This is the most dangerous attitude of all. If this roof has problems, the expense of repairing it later could be many times the cost of the original job. Use the best tools available to determine if the existing roof and substrate can be sprayed over without repair or tear-off. Even if the substrate appears okay, some codes require tear-off. Check ahead of time- before you get in trouble.

Overspray:

Wind screens and enclosures help prevent overspray damage

If the wind is coming from a specific direction, multiple windscreens

can block the wind without having to use a complete enclosure.

Helpers waiting for the applicator.

Note: helpers holding the screen should wear air purifying respirators.

The roof looks great and will last for 30 years. But the owner’s car, patio, windows, bushes, flowers, and dog have a bright sheen of SPF overspray semi-permanently attached to them. All overspray is preventable. When you cannot shield, or move items to prevent overspray, use windscreens or STOP SPRAYING!

“Get the Work Done” Greed:

All SPF roofing requires favorable environmental conditions--not too much wind, moisture, right temperature, etc. Applicators need to know how many hours they can spray each day before dew hits, or it gets too cold or too hot. If you calculate 5 hours of prime spray time, don’t spray for 5-1/2 hours. Make sure you have enough time to coat everything you sprayed and for darn sure, keep an eye on the changing weather.

Surface Preparation:

Before installing a new roof, check out the substrate and fascia. Note the deteriorated nailer and edge flashing.

What kind of surface are you spraying to? How do you clean it? What type of contaminants are on it? Does it need a primer? Does it need sandblasting, vacuuming or pressure washing? If you don’t have good answers to these questions, you will be going back on a lot of your jobs and your profit will go down the drain.

Wrong System:

Yes, you can use the wrong foam, coating or membrane. Identify the performance requirements of the roof before bidding the job. I had a homeowner ask me if his new 25-mil coated SPF roof would hold up well with tables and lawn furniture on it because he used the roof as a patio deck. What was the contractor thinking? Listen to your customer; ask him questions on the expected performance. There are SPF roofing systems that would work for this project, but not what the contractor sold him.

In Conclusion:

SPF roofing systems have demonstrated exceptional performance in most applications. But, it requires training and experience to do the job right. If you want to become a spray foam-roofing contractor, do your part to continue the upward trend towards quality work.

Get the right equipment, take into consideration the weather, and get the right training and experience. Another important point to end this discussion: START SMALL!!! Don’t bid on a 100,000 sq. ft. job as your first job. Find some easy-to-prepare roofs that are in the 5 to 10,000 sq. ft. range. Have a training technician onsite to guide you through the whole process from substrate preparation to final inspection.

Good Luck and Good Spraying!

Contributing Writer/SPF Trainer Mason Knowles

Mason Knowles is President of Mason Knowles Consulting, LLC.

Providing technical consulting services for the polyurethane industry

Specialties

- Technical Training and Education

- SPFA Accredited Course Provider & Inspector

- SPFA Certified Field Examiner

- Sales and Marketing

- Presentations and Technical Writing

- Research Coordination (Underwriters Laboratory, Factory Mutual, etc)

- Building Code Compliance and Regulatory Advocacy

- Inspections, Roofing, Insulation, Safety and Health Programs